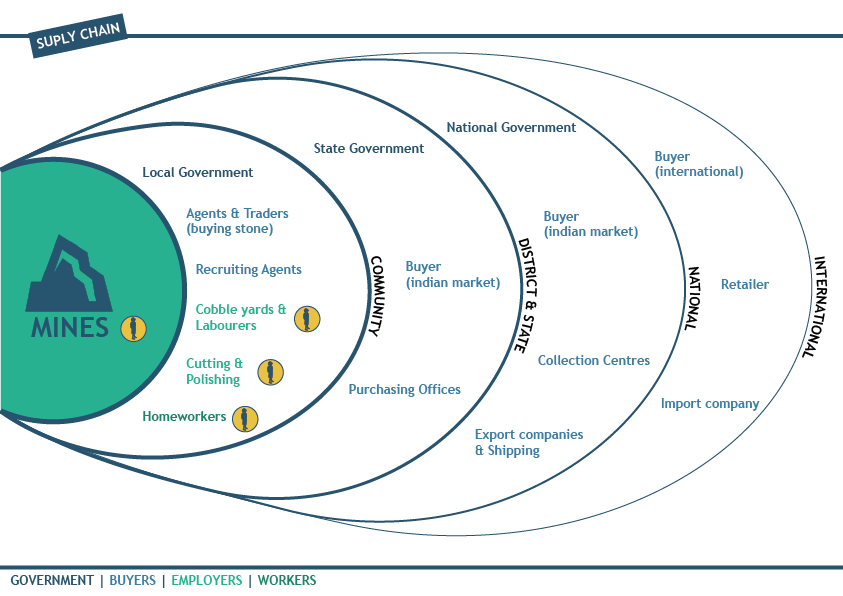

A variety of different businesses operate throughout the entire stone sector supply chain: mines, cobble yards, processing units, agents, traders and buyers. The lower tiers of the supply chain are the businesses that operate in Budhpura: the cobble yards and homeworkers involved in cutting cobbles and packing them for export.

Progress has been made in getting children out of work and into schools, but there is still a lot of work to be done to achieve child labour free stone supply chains and decent work for adult workers in the sandstone sector.

Sandstone mines

Sandstone blocks are quarried from areas rich in this natural resource. The waste stone is sold to traders and transported to yards and homes for cobble-making. The majority of the sandstone quarried is for the domestic market, while cobbles are mainly for export and slabs are both for export and domestic use. The mines operate informally: workers do not have contracts and are hired via contractors, often with advance payments. Health & safety is a serious issue in the sandstone mining and processing industries. The mines are unmarked and do not display company names, which makes it difficult to identify the mine workers’ employers.

Manjari runs a motivation centre in one of the mine sites

“If Manjari didn’t have the motivation centre here, children would not be able to play and learn. They would just roam around by themselves, as their parents leave for work early in the morning. Education is the only way you can train for work other than stone-cutting. If you don’t know how to read and write there’s no other chance.” Female worker who lives in a mining village.

Cobble yards

In cobble yards, sandstone cobbles are collected, sorted (by size and colour), finished (edged and calibrated) and packed into wooden crates for export. There are about 25 cobble yards, with clear boundaries, and most of them have a sign with the company name and ‘Child Labour Free Zone’.

Nowadays most of the cobbles, about 80%, are cut in homes and open spaces on the roadsides in the community. The remaining 20% of the cobbles are cut in the cobble yards. The yards thus mainly function as a location where cobbles are collected, finished and packed for export. The yard owners and cobble traders are organised in a cobble-traders’ association. The dialogue with cobble traders has resulted in initial improvements in the yards.

Processing unit

In a processing unit, the sandstone blocks are cut into slabs and tiles of the required sizes, then finished through polishing. Most workers who cut, polish and pack the stones are daily wage labourers. The managers in processing units are formally employed, with contracts, while workers are often informal workers without contracts and social security.

Exporting companies

The exporting companies export natural stone products (often slabs, tiles and cobbles) to Europe and other markets. These companies usually export granite, limestone and marble in addition to sandstone. Exporting companies indicate that foreign buyers of sandstone cobbles source cobbles everywhere, shopping around for the lowest price. Some of the exporting companies are integrated companies: they are involved in exporting sandstone slabs and cobbles but also own processing units and mines.

“As our clients expect us to be responsible, we also want our clients to treat us fairly. We expect to work with ethical companies in the production chain.”

Navneet Bansal, quarry owner